Knowledge of Electroplating : Types and Methods of Electroplating

Electroplating

We’ve all heard the terms “gold plated” or “silver plated,” but what exactly is plating? What are the different types and methods of electroplating?

Electroplating is a process in which a thin layer of metal is deposited onto the surface of another metal object using electricity. This can be used to improve the appearance, conductivity, durability of the object, or to protect it from corrosion.

Characteristic Electroplating

With the aesthetic of society rising, the single-color plating technique is no longer sufficient to meet the needs of the majority of people. As a result, more and more distinctive electroplating techniques emerged. In addition, we used two distinct electroplating techniques at a higher frequency.

One is Antique Electroplating, in which we use black dye on the metal accessory after electroplating to create an antique style. And the other is Double Color Plating, which is a technique that covers the metal surface with two colors, but the cost is higher because of its performance.

Methods of Electroplating

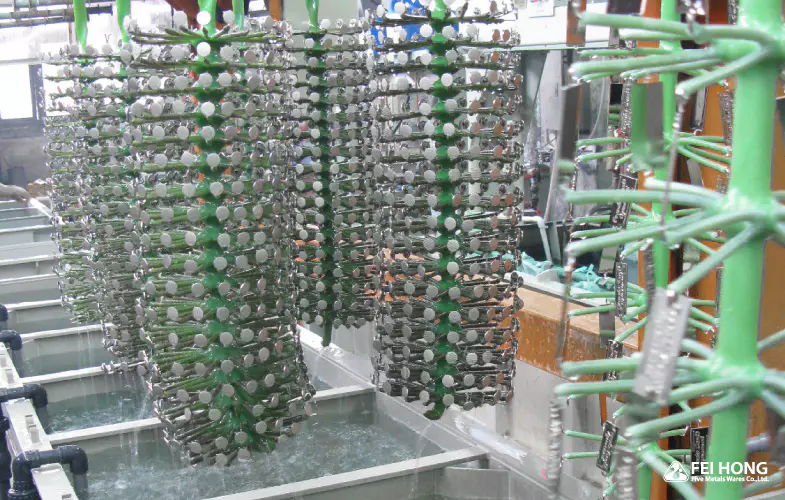

Hanging Plating

The most common method is hanging plating. Hang the metal accessories on the appropriate hangers, then place them in the electroplating tank and use the plating process to process them. The hanging plating technique allows you to do the process for more products at once, with fewer deviations from the amount.

The process concepts of hanging plating and rolling plating are the same; however, hanging plating has a higher craft level and can make the metal surface flat and shiny. Its flaw is that it requires a lot of time and people to hang the metal accessories on the hangers.

Rolling Plating

Rolling plating requires less space than hanging plating and does not require people to hang on the accessories, so the cost is lower. The preprocessed accessories are placed in the bucket before rolling plating. Place the bucket in the electroplating tank and begin rolling it to plate all of the metal accessories in the bucket. Its benefits include increased productivity, lower costs, and the need for a small space; however, its drawbacks include the plated layer being too thin or of poor quality, and the surface being prone to bubbles, scratches, or contaminants.

Plating Preprocessing and Follow-up Processing

To improve the electroplating manufacturing process and, ultimately, to produce a high-quality plated product. Preprocessing prior to plating, as well as checking and repairing after electroplating, are critical.

Hanging plating is the most common plating method used by most factories; some factories will assemble and disassemble themselves in the section that places the products on the hangers to save money on plating factories.

If the electroplating preprocessing is incorrect, it frequently results in poor phenomena such as stratification, peeling, and plating layer detachment. To reduce product loss, it is necessary to check the surface for oil stains, sand particles, and so on before sending it for electroplating. Following electroplating, it is also necessary to inspect the electroplating surface for particles, bubbles, and other defects, as well as to strictly inspect the customer’s product.

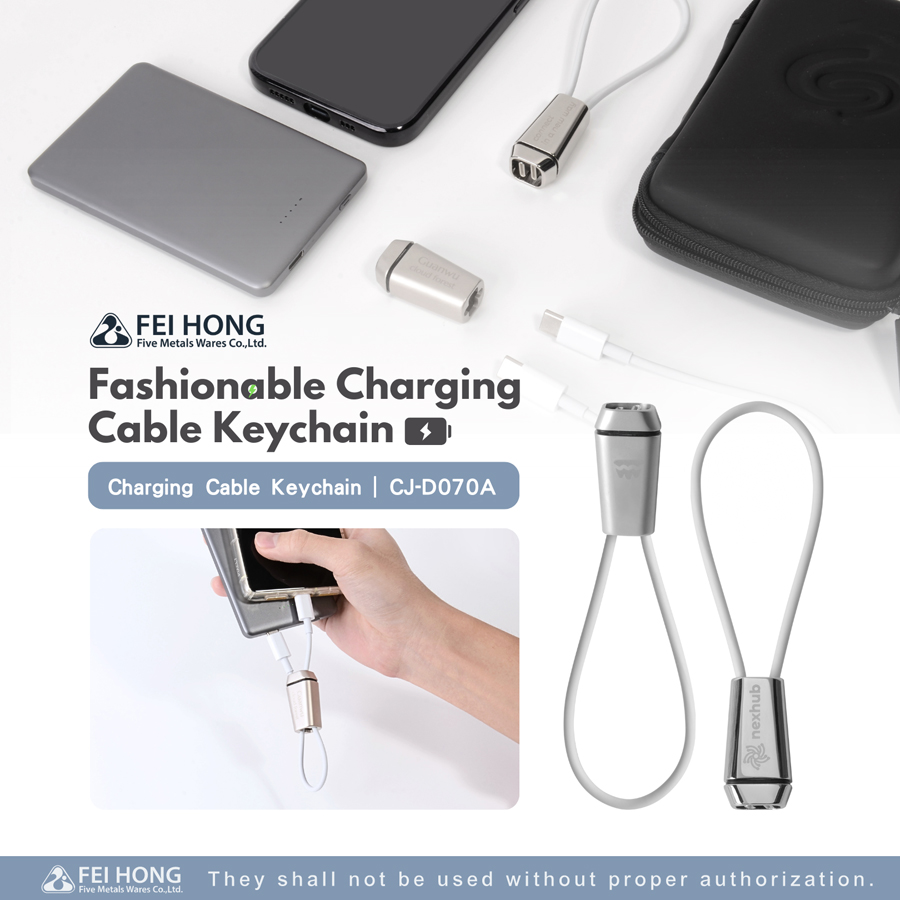

Professional Electroplating Technique from Fei Hong Five Metals

Since the beginning of designing, molding, feeding and discharging the material, and polishing, Fei Hong has taken every precaution to reduce the rate of failure to show the metal shine of the product. The plating material can also have an impact on the plating effect; Fei Hong’s plating liquid is pure and eco-friendly. We use the most professional plating technique, and we will work hard to create each product for you. Please contact us or hold an online conference with us to create your one-of-a-kind plating product.