What is Zinc Alloy Die Casting?

Introduction

As a company with zinc alloy gifts manufacturing experience for many years. Zinc alloy die casting is the most important and fundamental technique, but what is die casting? Is there any detail we need to know during the process of die casting?

What is die casting?

Most metals used for die casting are zinc, aluminum and magnesium. After melting, inject the liquid metal into the mold made of iron by high pressure. The liquid metal will be cool and solid, and at the end turn out to be a cast. Die casting is a common process used for mass manufacture. Each mold represents each product, and the process can manufacture products correctly and continuously.

Zinc Alloy Die Casting

In zinc alloy die casting, the most common zinc alloy material which is called Zamak 3, is suitable for lots of gifts and accessories because of its excellent plating and finishing characteristics. Great zinc alloy is stable when die casting, and it will be shiny after the process.

Zinc alloy is the most appropriate material to make custom products, the surface of zinc alloy can be colored by plating and other ways easily. The melting point is lower than other metals, so you can spend lower energy in the melting situation before casting. Because of the melting point, it can also extend the life of mold, and be more eco-friendly.

How to make a blank?

The product wasn’t decorated or polished after die casting which is called “blank”. However, how to make a blank ? First, the liquid metal goes through the sprue, runner, gate, and ends up at every cavity. After the temperature of liquid metal cools down, the metal will be solid and that is called “blank”. And the following articles are the introduction of different places of the process.

Sprue:This part is the first place liquid metal goes through, liquid metal will go into runners from sprue.

Runner:The liquid metal can be distributed equally from the runners.

Gate:The way connected from the cavity and runner, the wall of metal is thinner so that it is convenient to cut it off the accessories from the system.

Cold-slug-well:To prevent the temperature of liquid metal from becoming too low on the top of the nozzle, it will make liquid metal enter in the zone. The function of the zone is to make the temperature of liquid metal balance, so the quality and the density will be in a stable situation.

Management of Quality Stability

Depending on the different metal materials, the temperature of the oven and the pressure of injection should be adjusted. If necessary, the cooling system should be found to keep the size of products and make it stable. The most common problem of zinc alloy die casting is metal blisters on the surface. To avoid the situation, the stability of liquid metal injection and the design of mold are important. Both of them may cause the production of blisters.

To prevent manufacturers from using unknown metal materials for production and affecting the quality of the products, there are many third-party certification agencies in the world that provide complete audit and certification services. In addition to avoiding the use of inferior materials, they can also ensure stability and consistency. The zinc alloy materials used by Fei Hong Five Metals Wares Co., Ltd. have passed the international TUV certification. The zinc alloy products we produced and sold are all qualified.

Conclusion

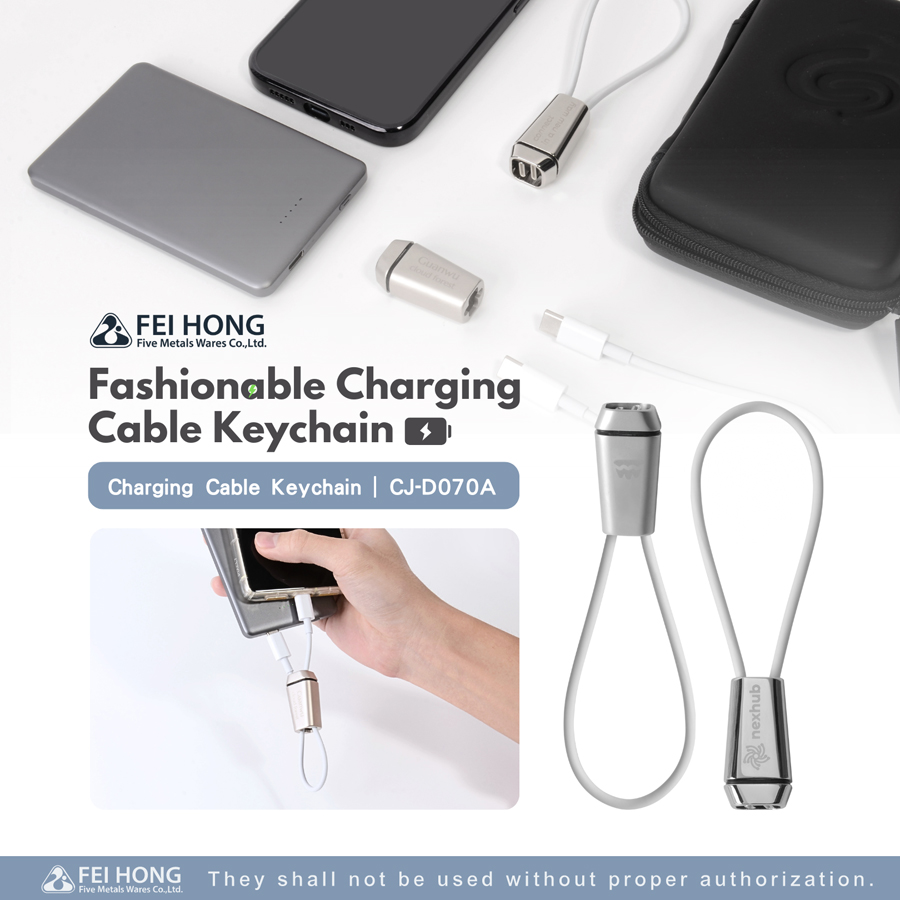

Zinc alloy die casting is a necessary technique in metal accessories manufacturing. According to the factors like temperature, pressure, and the design of mold, the quality of the products from each factory is different. Fei Hong Five Metals Wares Co., Ltd. specializes in zinc alloy manufacturing for nearly thirty years, and we also keep improving our manufacturing skills and hope to bring the best quality to our clients. We provide custom zinc alloy key chains, badges, phone ring holders, etc. If you have any request, please feel free to have a reservation on web conferencing with us to know more product information, or discuss your idea with us, let us make exquisite zinc alloy products together.